Tuesday, August 11, 2015

My Band Saw Circle Jig

Saturday, August 8, 2015

Home Made Box Joint Jig

I made this box joint jig (sometimes called finger joints) for my table saw. It was intended to be used with dado blades on the saw. I built it and as I was putting the dado blades on the saw in order to make the first key plate, I realized that this old saw won't take dado blades. They don't fit on the blade spindle. Bummer! Now what?

Then I remembered I have a router table for my router, and with a slight modification I could make this fit the router table. I only had to make a different sized miter slot guide.

Here's how it works: The jig has an interchangeable key-plate, one for each size finger joint you want to make. I made three: a 1/4 in., 3/8 in. and 1/2 in. plates, held in place with 2 screws. Shown above is the 1/4 in. plate. You put on the key plate that you want to use and make a test cut. After the first cut, the slot you just cut is moved over and place over the "key", and make another cut. Repeat those steps for each cut. If needed, that black front plate can be adjusted with the micro-adjustment screw at the end of that plate. The plate is then tightened in place with wing nuts (on the back side).

What is nice about this jig is that you can cut all the finger joints for your box at the same time by stacking the wood and then putting a clamp on it so nothing moves. This jig is amazingly precise for something I just whipped out in one afternoon.

Below is a photo of the first two boxes I made with this jig. There's a bit of tear-out on a few of the finger joints; a problem I've since remedied using a sacrificial piece of wood on the blade side of the stack of wood when cutting. Both boxes are made of the same wood; oak tops and bottoms and spruce for the sides. The larger box is stained. The small box, not stained, is 2 in. square on the top, a little less on the sides.

Then I remembered I have a router table for my router, and with a slight modification I could make this fit the router table. I only had to make a different sized miter slot guide.

Here's how it works: The jig has an interchangeable key-plate, one for each size finger joint you want to make. I made three: a 1/4 in., 3/8 in. and 1/2 in. plates, held in place with 2 screws. Shown above is the 1/4 in. plate. You put on the key plate that you want to use and make a test cut. After the first cut, the slot you just cut is moved over and place over the "key", and make another cut. Repeat those steps for each cut. If needed, that black front plate can be adjusted with the micro-adjustment screw at the end of that plate. The plate is then tightened in place with wing nuts (on the back side).

What is nice about this jig is that you can cut all the finger joints for your box at the same time by stacking the wood and then putting a clamp on it so nothing moves. This jig is amazingly precise for something I just whipped out in one afternoon.

Below is a photo of the first two boxes I made with this jig. There's a bit of tear-out on a few of the finger joints; a problem I've since remedied using a sacrificial piece of wood on the blade side of the stack of wood when cutting. Both boxes are made of the same wood; oak tops and bottoms and spruce for the sides. The larger box is stained. The small box, not stained, is 2 in. square on the top, a little less on the sides.

Friday, July 31, 2015

Mobile' #55

I've made a couple of large mobile's this month. It started out as one mobile' but it didn't look right so, I made two mobile's instead. The first is #54 not shown here. The second was this one shown above. It is a little over three feet tall and about eight feet long. All the rods are steel, painted black. The base is a maple tree branch. The other wooden elements are assorted wood species: eucalyptus, western maple, silver maple, cedar and plum. All the wood is stained the same color for consistency.

I like to set up the large mobile's in my backyard for a week or so to see how they will behave. If there are any flaws in the design or construction, nature will expose them. This one worked beautifully from the first set-up and lasted the week without any tweaks or repairs. I thought, "OK, time to finish it of with a coat of paint on the steel and I'll do that right now." I turned to walk out the back door and this is what I saw.

That's a twenty foot long maple branch that broke off the tree the mobile' was under. That green stuff is mistletoe, which is really heavy. That's why the branch broke. It completely smashed the mobile'. Luckily, it didn't break the base. I was able to rebuilt this mobile' in a couple of days. It's now on a pedestal in my front yard. It looks great and is beautiful to watch. It is for sale if you're interested.

You can see all my mobile's on my art web site: http://www.tesserak.net/html/mobiles.htm

Here's a video clip of the mobile the day before it was crushed.

I like to set up the large mobile's in my backyard for a week or so to see how they will behave. If there are any flaws in the design or construction, nature will expose them. This one worked beautifully from the first set-up and lasted the week without any tweaks or repairs. I thought, "OK, time to finish it of with a coat of paint on the steel and I'll do that right now." I turned to walk out the back door and this is what I saw.

That's a twenty foot long maple branch that broke off the tree the mobile' was under. That green stuff is mistletoe, which is really heavy. That's why the branch broke. It completely smashed the mobile'. Luckily, it didn't break the base. I was able to rebuilt this mobile' in a couple of days. It's now on a pedestal in my front yard. It looks great and is beautiful to watch. It is for sale if you're interested.

You can see all my mobile's on my art web site: http://www.tesserak.net/html/mobiles.htm

Here's a video clip of the mobile the day before it was crushed.

Friday, February 20, 2015

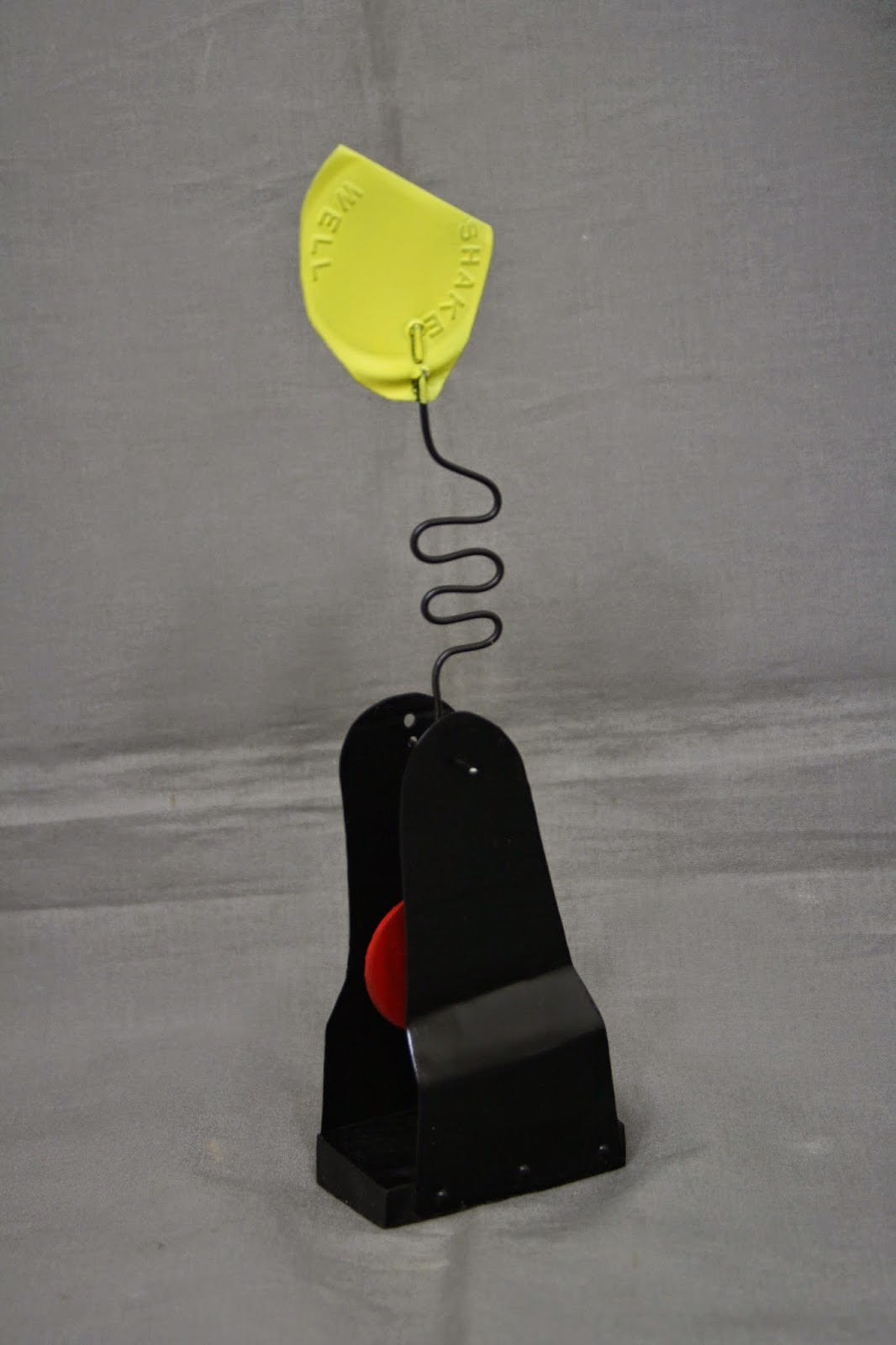

Mobile' #52

Here's another small wire mobile', #52. A pivot-on-point type mobile' with a stretched square spiral balanced on a stand. Painted paper tags will catch the slightest air currents, spinning the spiral. See it in action on my YouTube channel.

Tuesday, February 3, 2015

Another new mobile', #51

Here's another little mobile' sculpture. This one is all mild steel wire about 6"H x 3.5"W. It's a pivot-on-point type mobile. Of course it looks a lot better in motion. See it in action on my YouTube channel:Mobile' #51 video clip.

See all my mobile' sculptures on my art studio web site at: Tesserak Art Studio Web Site

See all my mobile' sculptures on my art studio web site at: Tesserak Art Studio Web Site

Sunday, January 25, 2015

A couple of mobile' prototypes.

Here are a couple of new mobile's. These are prototype models for larger full-size mobile. These ones are about 9 inches tall, made from steel food cans, wire and some big steel washers. These are pendulum-type mobile's. I made these in December 2014.

My Tiny Swiord

I made this tiny, hand-forged, sword. Just fooling around in my shop one day. This is made from two nails, heated up and hand-forged, ground and polished. No particular reason for making this. Just to see if I could make it. It took about an hour.

Subscribe to:

Comments (Atom)